Product Features:

High-voltage line rod-shaped composite insulators are composed of three parts: insulating core rod, silicone rubber umbrella sleeve and connecting hardware at both ends. The insulating core rod is the abbreviation of epoxy resin glass fiber pull-out rod. It is the skeleton of the composite insulator, supporting the umbrella sleeve, internal insulation, connecting the hardware at both ends, and bearing mechanical loads. It has a very high tensile strength, generally up to 600Mpa or more, which is twice that of ordinary steel and 5-8 times that of porcelain materials. It has good dielectric properties and chemical corrosion resistance, as well as good resistance to bending fatigue, creep and impact resistance.

The silicone rubber umbrella sleeve mainly protects the core rod, blocks wind and snow, increases the creepage distance and the external insulation of the product. It is based on high molecular polymer silicone rubber, supplemented by flame retardants, anti-aging agents, coupling agents and other fillers, and is vulcanized at high temperature and high pressure. It has good hydrophobic migration, as well as good corrosion resistance, aging resistance, electrical insulation and other properties. It also has very high pollution flashover voltage and crushing resistance, and the voltage distribution is uniform. Compared with porcelain, its flashover voltage is more than twice that of porcelain under the same conditions (porcelain is 1/8 of the insulator). It is small in size, not easy to break, has high tensile strength, and is easy to transport.

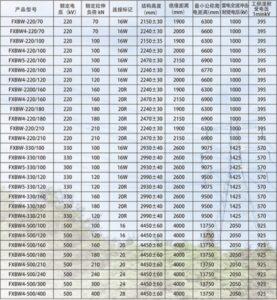

(The parameters in the table are for conventional products and can be customized.)

Reviews

There are no reviews yet.